Geocell Plastic Sheet Extrusion Machine

| Parameter | Specification |

|---|---|

| Model | AI-GE/EXTRU-1000 |

| Material | HDPE / PP (High-Density Polyethylene / Polypropylene) |

| Sheet Width | Up to 1200 mm (adjustable) |

| Sheet Thickness | 1.0 mm – 2.5 mm (tolerance ±0.05 mm) |

| Production Capacity | 400–600 kg/hour (depending on sheet thickness and material) |

| Line Speed | 0.5 – 5 meters/min |

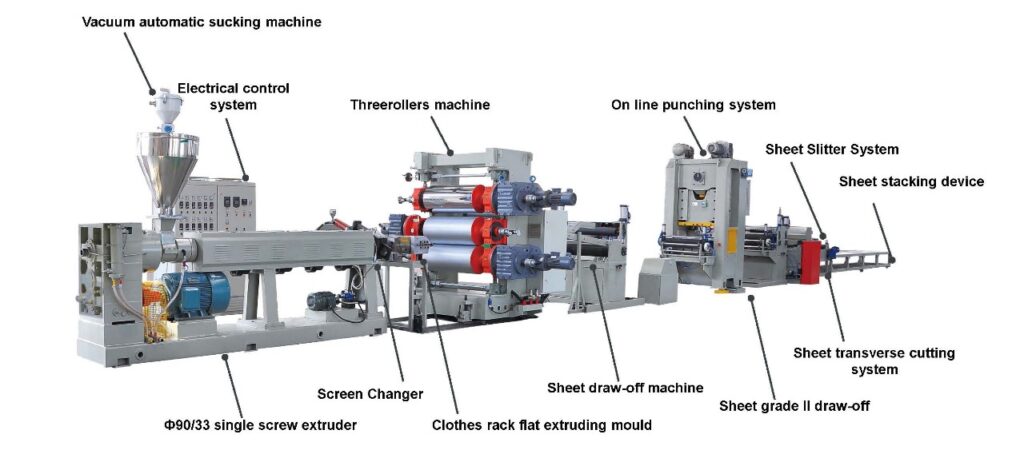

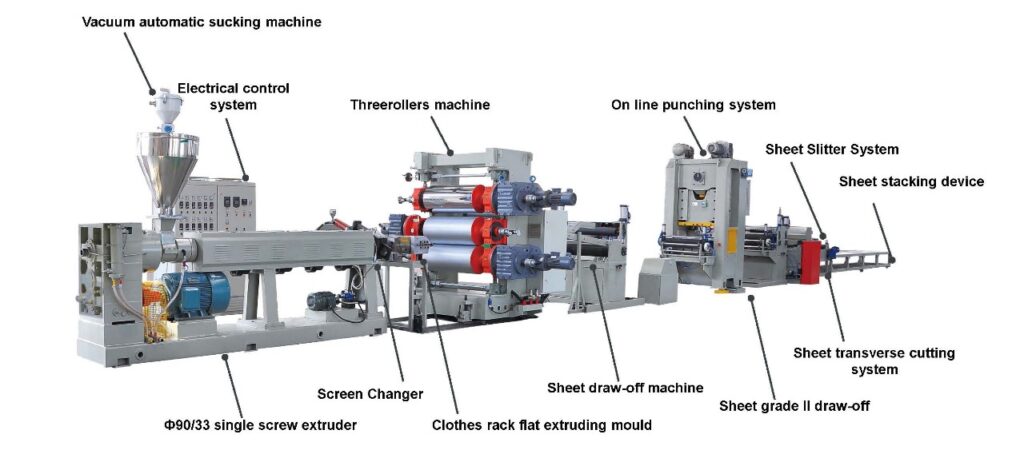

⚙️ Extrusion System

| Component | Specification |

|---|---|

| Screw Diameter | 90–120 mm (single or twin screw as per model) |

| L/D Ratio | 30:1 |

| Extruder Drive Motor | 75–110 kW AC Motor with VFD |

| Heater Zones | 6–8 (PID temperature controlled) |

| Cooling Zones | Air + water cooled barrel sections |

🧊 Calendering & Cooling Unit

| Component | Details |

|---|---|

| Calender Rollers | 3-Roller system (chrome-plated, temperature controlled) |

| Cooling Method | Water-cooled roller system |

| Roller Width | Up to 1300 mm |

| Surface Finish | Smooth or textured (optional) |

🖥️ Control & Automation

| Feature | Details |

|---|---|

| PLC Control System | Siemens / Delta with HMI Touchscreen |

| Operation | Centralized control panel with alarm diagnostics |

| Parameter Monitoring | Temperature, speed, thickness, pressure |

✂️ Cutting & Winding System

| Component | Specification |

|---|---|

| Cutting Type | Rotary shear or flying blade cutter (optional) |

| Winder | Surface or center winder with tension control |

| Winding Diameter | Up to 1000 mm rolls |

🔒 Safety & Quality Assurance

• Emergency stop switches at key locations

• Overload protection on all motors

• Automatic material level detection and feeding

• CE-compliant design (optional for export)

• Overload protection on all motors

• Automatic material level detection and feeding

• CE-compliant design (optional for export)

🧩 Optional Features

• Embossed sheet surface for better friction (Anti-slip)

• Gravimetric feeder for raw material accuracy

• Online thickness gauge system

• Corona treatment for better surface bonding

• Auto-tension control for consistent winding

• Gravimetric feeder for raw material accuracy

• Online thickness gauge system

• Corona treatment for better surface bonding

• Auto-tension control for consistent winding

Key Features:

High Speed Production

Enables simultaneous for faster production and high uniformity.

Fully Automatic Operation

Strip feeding, positioning, cutting & punching, and output handled automatically.

Touchscreen HMI Interface

Intuitive controls for operation, recipe management, and diagnostics.

Servo-Based Motion Control

High precision for consistent weld positioning.

Adjustable Parameter

Pressure, and duration settings configurable for different material grades.

Safety

Integrated sensors and safety enclosures for operator protection.

Application Areas

Erosion Control & Slope Stabilization

Road & Railway Foundation Layers

Mining Roadways & Military Access Roads

Soil Retention Systems

Why Choose This Machine?

- Unmatched Production Efficiency

- Adaptable to Your Needs

- Precision Engineering for Zero Defects

- User-Friendly PLC Touch Interface

- Built for 24/7 Industrial Use

- Custom Power Configuration

- Minimal Downtime, Easy Maintenance

- Backed by Expert Support

Need Help Choosing the Right Machine?

Our experts are ready to assist you. Whether you’re expanding production or entering the geosynthetics market, we offer tailored solutions to fit your plant and production goals.

Contact Us Today for demo, pricing & customization options